Infrastructure

IT Assets

| Software | Make |

|---|---|

| TruTops Boost Programming | TRUMPF |

| TruTops Tube Designing and Programming | TRUMPF |

| Solid Works for 2D/ 3D Designing | Dassault |

| Solid Works for Sheet Metal Designing | Dassault |

| Administrative Applications | Certified Microsoft Products |

| ERP | Customised as per IATF Requirements |

| Quality Measurements | Innovative Make |

Machinery Details

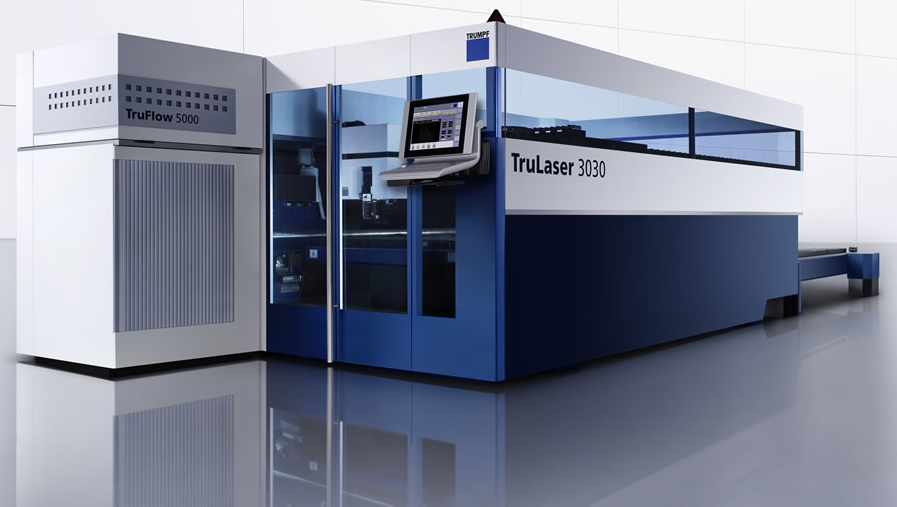

TruLaser 3030 L20 with Rotolos

| Benefits | Description | TruLaser 3030 L20 |

|---|---|---|

| Laser Power | TruLaser Power | 4.0 kW |

| Working range | - | 3,000 x 1,500 x 115 mm |

| Maximum Speed | Axially parallel Simultenious | 100 m/ min 140 m/ min |

| Workpiece weight | Max weight in kg | 900 kg |

| Highspeed cutting | High-pressure cutting with nitrogen: Rapid cutting at | Up to 40 m/ min |

| Accuracy | Smallest programmable increment approx. Postioning accuracy approx. Pa Repatibilty approx. Ps | 0.001 mm ±0.1 mm ±0.03 mm |

(Source: TRUMPF Group)

TruBend 3100 (B26)

| Benefits | Description | TruBend 3100 (B26) |

|---|---|---|

| Press Force | - | 1000 kN |

| Stroke | - | 445 mm |

| Maximum Speed | Travel in R3 / 1 Travel in Z3 / 1 Travel in X3 / 1 | 200 mm/ sec 1,000 mm/ sec 500 mm/ sec |

| Inclination of beam | - | ±6.5 mm |

| Bending length | - | 3060 mm |

| Throat | Max flange width for full length | 430 mm |

| Operating height | Working position height | 1,049 – 1069 mm |

| Travel path X Axis | - | 600 mm |

| Accuracy | Dimensional Angular | 0.1 mm ± 0.5 Deg |

(Source: TRUMPF Group)

Special Purpose Machine – CNC

| Benefits | Description | Special Purpose Machine – CNC |

|---|---|---|

| Spindle Capacity | Tube Cutting | Upto 65 mm |

| Working range | Max. Diameter Max. Length | 65mm 150 mm |

| Maximum Speed | Programmable Spindle Speed s, VFD | 1080 RPM |

| Production Rate | Max Pics per Hour, Based on Part size | 350 to 600 Nos |

| Customized | Bar Feeder Mechanisum, automatic Servo operated Tailstock for length setting Pneumatic operated special collect chuck PLC base Electric control panel | Upto 4000 mm Up to 150 mm Up to 65 mm Length selection Programmable stopper Programmable speeds |

| Operation to be planned | Tube Parting Opeartion |

Vibro

| Benefits | Description |

|---|---|

| Requirements | 100% Seperation of Component On line washing and Burr removal Fully Automatic Process Stain Free Drying Sound Absorbing Cover |

| Solutions | Vibro Sprial System of 900 Ltr. Capacity Manual Flapper Assembly and Sound Cover Auto Drain facility Online Washing and rust preventive system Vibro Dryer of 500 Ltr capacity PLC based Centralised Control Panel with VSD Automatic Processing Cycle |

| Make | - |

| Application | Vibro + Polishing and drying |

| Operation | Deburing + Washing + Polishing + Drying |

Tube Length Measuring System/Machine

| Benefits | Description | Tube Measuring System |

|---|---|---|

| Working range | Max. Diameter Max. Length | 65mm 150 mm |

| Production Rate | Max Pics per Hour | 2000 Nos |

| Customised | Indexing Mechanism, automatic Input and Output Rotary Table Input and Output Slat Conveyor Indexing system for Inspection and Rejection 8 Station Indexer withdwelltime1Sec. VFD Control PLC base Electric control pane | Length selection Diameter selection Programmable stopper Programmable speeds |

| Operation to be planned | Tube Length Measurement | - |

Previous

Next

SPM - Rework

| Benefits | Description | SPM - Rework |

|---|---|---|

| Spindle Capacity | Tube Cutting | Upto 65 mm |

| Working range | Max. Diameter Max. Length | 65mm 1000 mm |

| Maximum Speed | Programmable Spindle Speed s, VFD Quick Stop | 1080 RPM |

| Production Rate | Max Pics per Hour | 150 Nos |

| Customised | Pneumatic operated special collect chuck PLC base Electric control panel Special Internal and External Stooper | Up to 65 mm Length selection Programmable stopper Programmable speeds |

| Operation to be planned | Tube Parting Rework Operation | - |

Previous

Next

TruLaser Tube 5000

| Benefits | Description | TruLaser Tube 5000 |

|---|---|---|

| Working range | Outer Diameter Length of raw material Maximum Length of finished part Maximum Workpicece Weight | 150 mm 6500 mm 3000 mm 20 Kg/ m |

| Laser Capacity | TruFlow 3200 | 3200 W |

| Max. Material Thickness | Mild Steel Stainless Steel Aluminium | 6.4mm 4 mm 3 mm |

| Benefits | High Productivity Self Centering Clamps Reduce in conventional machining operation | - |

| Make | TRUMPF Germany | - |

Previous

Next

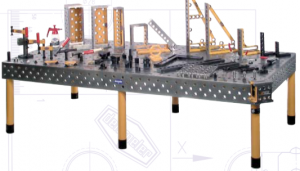

Welding Setup : In House

- 3D welding table and accessories by Dammeler Germany.

- MIG/ MAG Welding machine 270 Amps by Fronius Austria.

- TIG Welding machine 220 Amps by Fronius Austria.

- Welding Robot for Special Equipment’s

- Auto Pneumatic Leak Testing after Fabrication, Powder Coating

- High Pressure Hydro Testing

- WPS/ PQR Validation as per ASME section IX and AWS D 1.1

- Qualified Welders for GMAW/ GTAW

- Salt Water Testing for Paint

- Millipore Testing for Cleanliness

Previous

Next

Material Handling

| Name | Make | Count | |

|---|---|---|---|

| Pallet Truck 2T | Crown | Four |  |

| 2T Electric Fork Lift | Jungheinrich | Two |  |

| Scamlaz Sheet Metal Lifting Equipment | Schamalz | One |  |